Main Office (801) 462-2535

Main FAX (801) 972-1550

Dispatch FAX (801) 972-1557

SST Safety Courses - HazMat

Course C: Loading/Unloading and Placarding

Hazardous Materials shipments are generally very safe to transport if handled correctly. It is usually when improper packaging or handling takes place that an emergency situation exists. For this reason it is essential that proper loading and unloading methods are used in the transportation of these materials. The following methods/procedures must be followed:

- Use appropriate lifting methods/equipment to move HazMat shipments. For example, barrels should not be lifted with the forks of a fork lift. A barrel lift attachment should be used. (prevents punctured barrels)

- Never stack a corrosive on any other shipment. Corrosives must always be loaded on the floor

- Never load any type of poison, (i.e.: class 6.1 or class 2.3) in the same load as a food or food related shipment.

- Do not load incompatible HazMat's in the same load. Follow the segregation chart.

- Always complete necessary paperwork as the shipment moves through the system. (i.e.: manifest at the time of loading/unloading...don't wait until the trailer is loaded).

- Assure all shipments are secured in the load. Use straps, load bars, etc.

- Assure proper placards are in place (specifics will be discussed later).

- NEVER load a leaking HazMat (or any leaking shipment for that matter). If there is a spill or a spill potential the situation needs to be addressed prior to loading. Loading a leaking HazMat is a guarantee of a major problem down the road.

- If you discover a prohibited HazMat in our system immediately stop the progress of the shipment and report it to your supervisor. Prohibited HazMat's cannot not be carried in our system. (Prohibited HazMat's are discussed in Course A).

Some hazardous materials can be loaded with other hazardous materials with no problem. Other HazMat's should not be loaded with any other HazMat shipment. It is necessary to follow the Segregation Chart when loading HazMat's to assure that incompatible combinations of HazMat shipments are not loaded together. Below is an example of the segregation chart.

Click here to print HazMat Segregation Chart (front)

Click here to print HazMat Segregation Chart (rear)

The first section of the front page of the Segregation Chart displays a matrix that indicates whether or not a certain HazMat can or cannot be loaded with other HazMat's. If the box at the junction of two HazMat's is blank or open, then those two HazMat's can be loaded together. If there is an O in the box, then those HazMat's may be loaded in the same load as long as they can be segregated sufficiently so as to eliminate the possibility of mixing should one or both of them begin to leak. If there is an X in the box then those HazMat's are prohibited from being shipped in the same container/trailer.

This matrix also shows items such as the proper placard for each particular HazMat and the minimum quantity for which a placard must be used. There is also a notes column with alphabetical characters that refer to notes at the bottom of the chart that offer additional guidance points.

In the bottom right hand portion of the chart there are additional segregation requirements not able to be listed

in the matrix above.

The back page of the chart contains further guidance regarding compatibility and placarding. There is a section that

also covers placarding requirements for HazMat's with subsidiary hazards.

Hazardous Materials Placarding

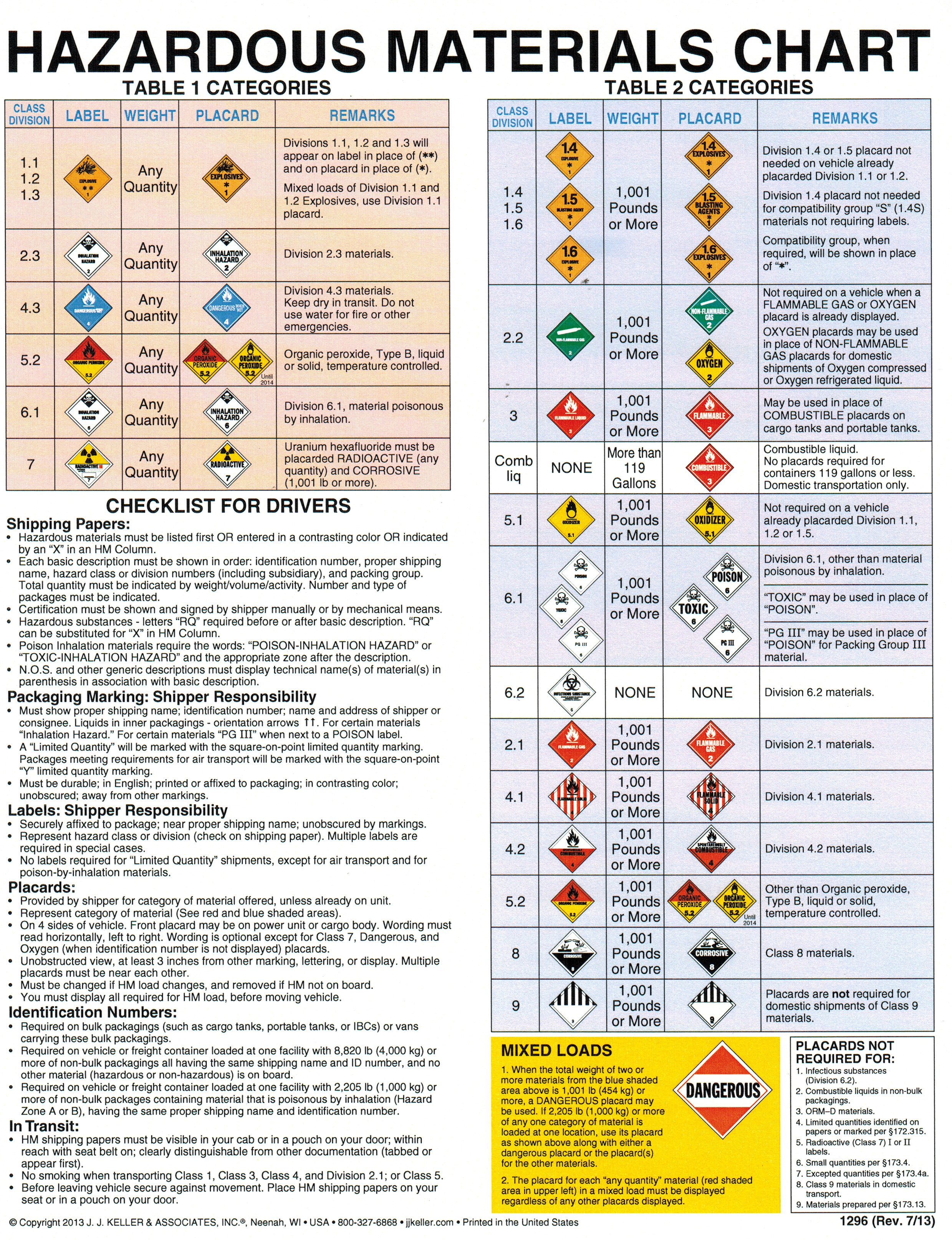

This Hazardous Materials Chart contains information that is useful in assuring that proper placards are placed

on the transportation units in which hazardous materials are loaded.

- Table 1 lists the categories of HazMat's that must be placarded in any quantity.

- Table 2 lists the categories for which placarding is required based on quantities/weights loaded. The chart shows the minimum quantities of each hazard class for which placards are required. This chart also has a checklist for drivers to help make sure all paperwork and other aspects of transporting HazMat's are in order.

- Though Dock employees are assigned the task of loading and placarding trailers, it is ultimately the responsibility of the Driver to assure this is done correctly.

Click here to print the Placard Info Chart

EXCEPTIONS: Some large quantities of HazMat shipments that would otherwise require placarding are exempt from the regulation. For example: Small arms ammunition in quantities over 1001 lbs. would normally require a 1.4s placard. However, if the small arms are packaged in consumer commodity packaging (packages less than 66 lbs.) then no placard is required for the shipment. The same is true for limited quantity shipments.

It is important to point out that placarding for a HazMat that is not in the load is against the regulations and would result in a violation being recorded if discovered on an inspection. In other words, it is illegal to placard for a hazard that does not exist. At the same time, it is illegal to have a hazard in the load and have no placard in place when it is required.

HOWEVER, it is perfectly legal to placard for a hazard that is in the load even though it may not be in a quantity that would require a placard. So the caveat "Better safe than sorry" applies in this scenario if you are not sure that the HazMat requires a placard or not.